These are some of the services offered by our Automation area:

- Design and Engineering

- Mechanical Manufacturing

- Automation

- Turnkey Projects

- Equipment Update

Request a Qoute

Design and Engineering

- Mechanical

- Hydraulic and Pneumatic

- Electric

- Studies and Process Simulations

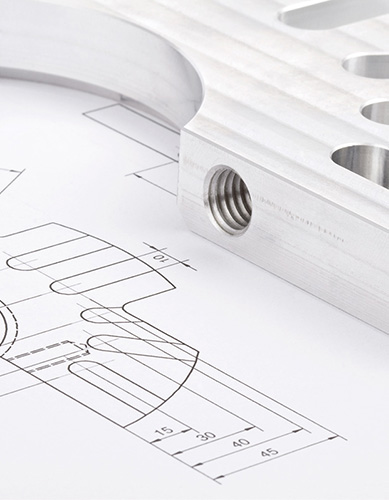

Mechanical manufacturing

- Pailer Structures

- Modular Structures

- Specialized Machining

- Robot Tools (EOAT), for cutting, loading and unloading, welding, among others.

- Machining fixtures, cutting, gauge, welding, among others.

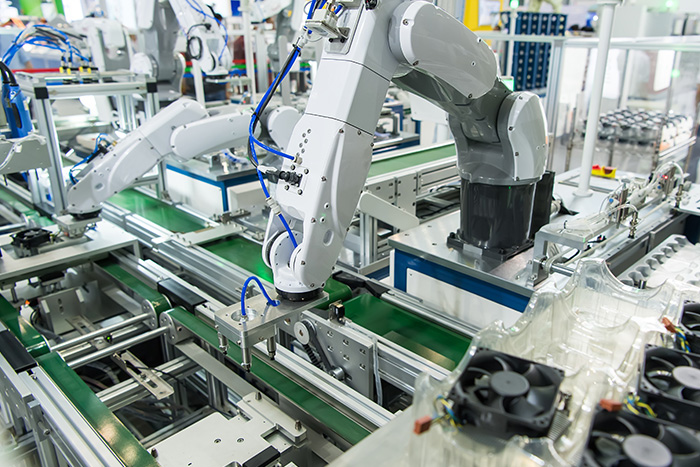

Automation

- Control and Power Boards

- Human-Machine Interface (HMI)

- Programming and Software Development

- Vision Systems

- Databases

- Safety Systems for Machines

- Robotics

Turnkey Projects

- Manufacturing cells for various processes

- Robot Integration

- Specialized Machinery for Machining centers, Quality,

- Food, Manufacturing, among others.

- Industrial Conveyors

Equipment Update

- Modification of existing equipment hardware and software.

- Reverse Engineering and Digitalization of Equipment

SERVICE

GMK Automation

Automation and integration of industrial processes

Nowadays automation is very common in the industry because it is a solution that offers various improvements to industrial processes.

The main objective of automation is to optimize production processes, increasing the amount of final product and reducing costs per piece.

What is it?

Automation is the application of automatic procedures for a process, through the application of different electrical, control, pneumatic, hydraulic and mechanical disciplines, as required by the application.

Learn more about our industrial automation services at: GMK Automation

When do you need to automate?

Automation is required in these cases:

- Reduction of operating costs.

- The production demand is very high, it exceeds the operating capacity.

- Quality problems in parts.

- Traceability in production.

- Improve operating safety systems.

- Quick flexibility for production.

How is your service working:

Our service begins through a need or problem of a client, based on this a detailed analysis of the process is generated to propose a better solution according to each type of need.

Client request

Analysis of the process and / or application

Solution development

Manufacture and assembly

Solution implementation

In case the solution is accepted by the client, GMK Automation undertakes to carry out the development of the solution, which consists of:

- Engineering and Design Development.

- Component Manufacturing.

- Acquisition of Commercial Components.

- Machinery Assembly.

- Tests, Adjustments and Equipment Conditioning (Internal Validation).

- Implementation of the Solution at the Provider’s Facilities

- Training for Operational and Maintenance Personnel for the correct use of the equipment.

- Delivery of Equipment Documentation

Industries that use this service

Automotive

Food

Metallurgical

Home appliances

General Manufacturing

Gemak Advantage

Lo que nos hace diferentes y la mejor opción para optimizar los procesos industriales de tu empresa:

- Commitment to Customer

- Flexibility in Projects

- Solutions tailored to your needs, from design solutions to turnkey projects.

- Infrastructure at the forefront, we have CNC machinery for the manufacture of components, welding area, laboratories for quality inspection.

- Highly trained personnel for the development and integration of automated solutions.

- Maintenance and operation training service for the correct use of the equipment.

- After-sales service.

Technical specifications.

GMK Automation is part of the Gemak Maquinados CNC group, which allows you to provide the highest quality component manufacturing and assembly service, with its machining centers and quality verification tools.