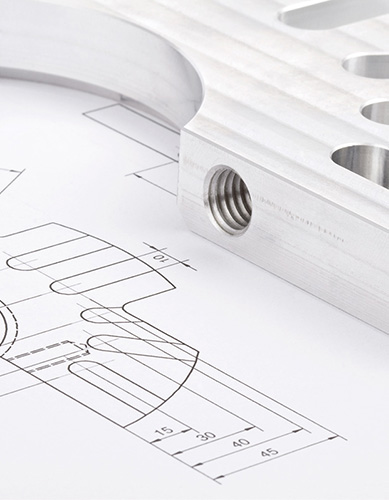

These are some products that can be made with CNC machining:

- Punches.

- Arrays.

- Extrusion dies.

- Precision keyways.

- Plastic injection molds.

- Cutting dies.

- Stamping and forging matrix.

- Tools.

- Dies for sintering.

- Special applications.

Request a Quote

Wire EDM

EDM is a thermal erosion process in which metal is extracted through a series of recurring electrical discharges between a cutting tool that acts as an electrode and a conductive part, in the presence of a dielectric fluid. This discharge occurs in a voltage gap (“gap”) between the electrode and the part. The heat from the discharge vaporizes minute particles of the workpiece and electrode material, which are then removed from the gap by the continuously flowing dielectric.

What is it for?

It is a non-contact process that does not generate vibration or cutting forces, which allows the production of very small, fragile and complex shaped parts. Tighter tolerances, intricate details and superior quality finishes can be obtained on a wide range of materials that are difficult or impossible to manufacture with traditional processes, plus burr-free edges are produced. Very hard metals can be worked because the process vaporizes the metal instead of cutting it.

It is also possible to machine explosive or flammable materials, because the process takes place within a fluid. EDM machines equipped with a process awareness function enable the production of complex parts with minimal operator intervention.

Industries that use this service

EDM is used in industry for high precision machining of all types of conductive materials such as metals, metal alloys, graphite, ceramics, among others, of any hardness.

Robotics and Automation

Mold Industry

Oil Industry

Automotive Industry

Farming Industry

Power Industry

Food Industry

Mining Industry

Construction Industry

Aerospace Industry

Gemak Advantage

We are a company that works under emergencies, special projects, and highly complex machined parts. We will always give you an immediate response to your need, proposing a better manufacturing option, innovating the best way to save time and money for the customer and all the attributes that we can provide to give confidence.

We have ISO 9001: 2015 Certification and 40 years of experience in machining, supporting the Mexican and foreign industries. In addition, we have quality control departments with the highest precision measurement verification teams.

Process

Requirement

we receive the RFQ from the client to start.

Quote

we verify if we have the capacity and we quote the project.

Agreement

We create the purchase order when both parties approve the project.

Manufacturing

we plan and manufacture the parts according to the drawing sent by the customer.

Inspection

we carry out inspections from the receipt of raw material, the first parts and a final inspection.

Packaging

we prepare the final pieces for shipment, protecting the pieces based on the customer’s requirement.

Delivery

we finally deliver the project, with the option of being at the door or being sent to its final destination.